Silicone Grommets for Surgical Kits

Project description:

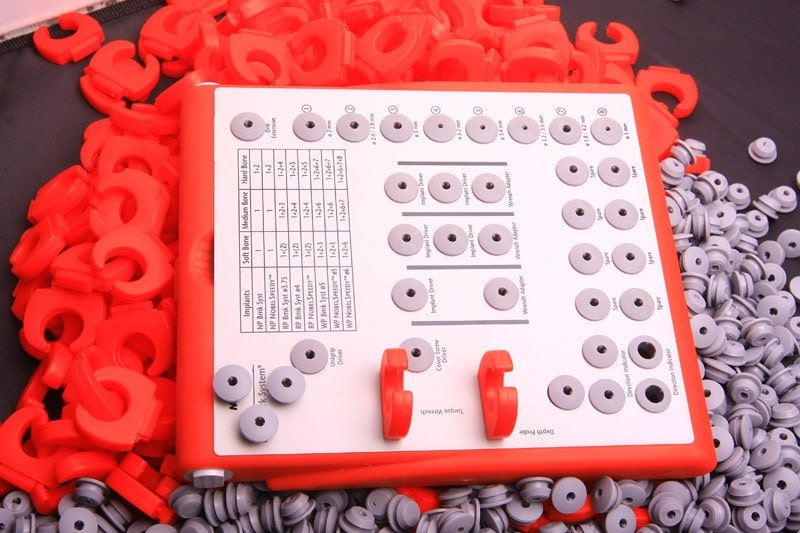

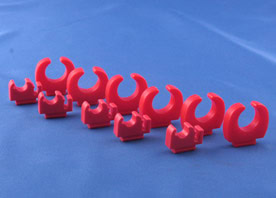

At Elastomer Technologies, our liquid injection molding capabilities combined with ISO Class 8 cleanroom production makes us a valued supplier to top tier manufacturers in the medical and dental device industries. We produced the silicone rubber grommets shown here in custom sizes for use in dental surgical kits.

Molded from Class VI medical grade liquid silicone rubber, these grommets featured dimensions of less than .750″ in diameter and a textured finish. Our modular tooling concept was an important factor in minimizing the initial tooling costs and reducing setup time. Multi-cavity mold inserts allowed us to produce numerous grommets from a single shot. By paying detailed attention to all aspects of the tooling construction, and pairing that with a controlled set of process parameters, we achieved close dimensional accuracy of ±.003″ and produced parts that were completely free of flash.

With our extensive experience producing health-care related products, we have a solid understanding of the quality requirements. Our robust, ISO-certified procedures incorporated first article approval, first off inspection, as well as automated 100% dimensional inspection and complete process validation. Final inspection involved verification of the part against the original drawing and our internally defined cosmetic standards.

We continue to produce these grommets in various colors in quantities that range from 10,000 to 200,000 units per order and ship them directly to multiple contract manufacturers. Our client is confident in the knowledge that the parts will be delivered accurately and on time. With our strong track record with this company, we have expanded our relationship and are 100% responsive to their fulfillment needs.

To learn more about our medical and dental industry capabilities, contact us today.

Silicone Grommet Project Details

- Capabilities Applied/Processes

-

Liquid silicone molding, multi cavity molds.

- Equipment Used to Manufacture Part

-

Liquid injection molding machines

- Overall Part Dimensions

-

Less than .750″ in diameter

- Tightest Tolerances

-

±.003 dimensional.

Flash requirement on finished parts.

- Material Used

-

Liquid silicone rubber (LSR) class VI compatible in various colors.

- Material Finish

-

Textured

- Industry for Use

-

Dental industry.

- In Process Testing/Inspection Performed

-

First article approval, first off inspection, in process inspection, final inspection to drawing and internally defined cosmetic standard.

- Volume

-

10,000-200,000 per order.

- Delivery/Turnaround Time

-

2-4 weeks.