Benefits of Professional Die Cutting | Elastomer Tech, Inc.

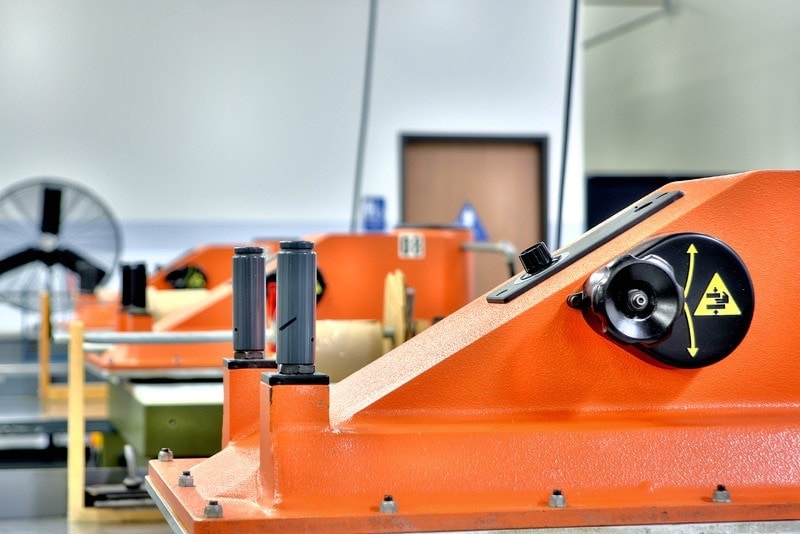

Die cutting is a crucial manufacturing process that utilizes specialized machinery to cut materials efficiently into precise shapes. Outsourcing die cutting services to professionals guarantees precision and quality, which are vital for functional and attractive products. With expertise in precision cutting techniques, professional services help businesses avoid defects, material waste, and financial losses, ensuring each…

Exploring Versatility and Benefits of Liquid Silicone Rubber

Liquid silicone rubber (LSR) is a specialized type of synthetic elastomer that remains liquid until it undergoes curing. It is typically processed through injection molding, where it is injected into a mold cavity and then cured to form the desired product. Its versatility and performance make it a popular choice for applications requiring high precision…

Liquid Injection Molding: The Future of Advanced Manufacturing

Liquid injection molding, or LIM, is a manufacturing process used to produce intricate parts from liquid silicone rubber (LSR). This technique is favored for its ability to create complex shapes, making it suitable for the automotive, medical, and electronics industries.

Why Use an Injection Molding Prototype

Injection molding is a manufacturing technique in which the molten material is injected into a hot mold cavity under high pressure. The material then cures and solidifies within the mold, taking its shape.

Rubber Products RMA Tolerances

Rubber Manufacturers Association (RMA) tolerances are significant in determining the acceptable deviation from specified dimensions or properties of a product. Thus, to maintain product quality and precision, manufacturers, engineers, and other stakeholders must understand RMA tolerances. Tolerance classes are denoted by letter codes, with A1 being the highest precision class and A4 being the lowest….

How To Choose the Right Die Cutting Partner

Die cutting is a manufacturing process that involves cutting out shapes from stock materials using a die, a specialized tool designed for cutting or shaping. This technique uses materials like paper, fabrics, rubber, metal sheets, and plastics.

When To Use Rubber Molding

Rubber molding is a versatile and cost-effective manufacturing process used in many industries for decades. It involves heating a rubber material and then pressing it into a mold to create a product with precise dimensions and intricate details. Moreover, it offers several advantages, including enhanced durability, flexibility, and affordability. However, the technique may not be…

Benefits of Reshoring Die Cutting

Manufacturers are gradually turning to reshoring, particularly in metal cutting and forming processes like die cutting. One reason is the increased customs complications caused by the COVID-19 pandemic, which demonstrated the potential risks with offshoring operations.

Benefits of Liquid Injection Molding for the Medical Industry

Injection molding is a versatile manufacturing technique used in the silicone industry for over a century. In particular, liquid injection molding (LIM) is a medical device manufacturing process with several advantages over other methods.

Response to Article Regarding Reshoring Medical Device Components

Due to a combination of the effects of the pandemic and geopolitical tension globally, there is a strong trend for reshoring manufacturing, especially with medical device components. Medical devices can be critical and having a predictable supply chain may outweigh the savings of producing offshore, at least in the current environment. An article by MDO…