Resources

Certifications

FAQs

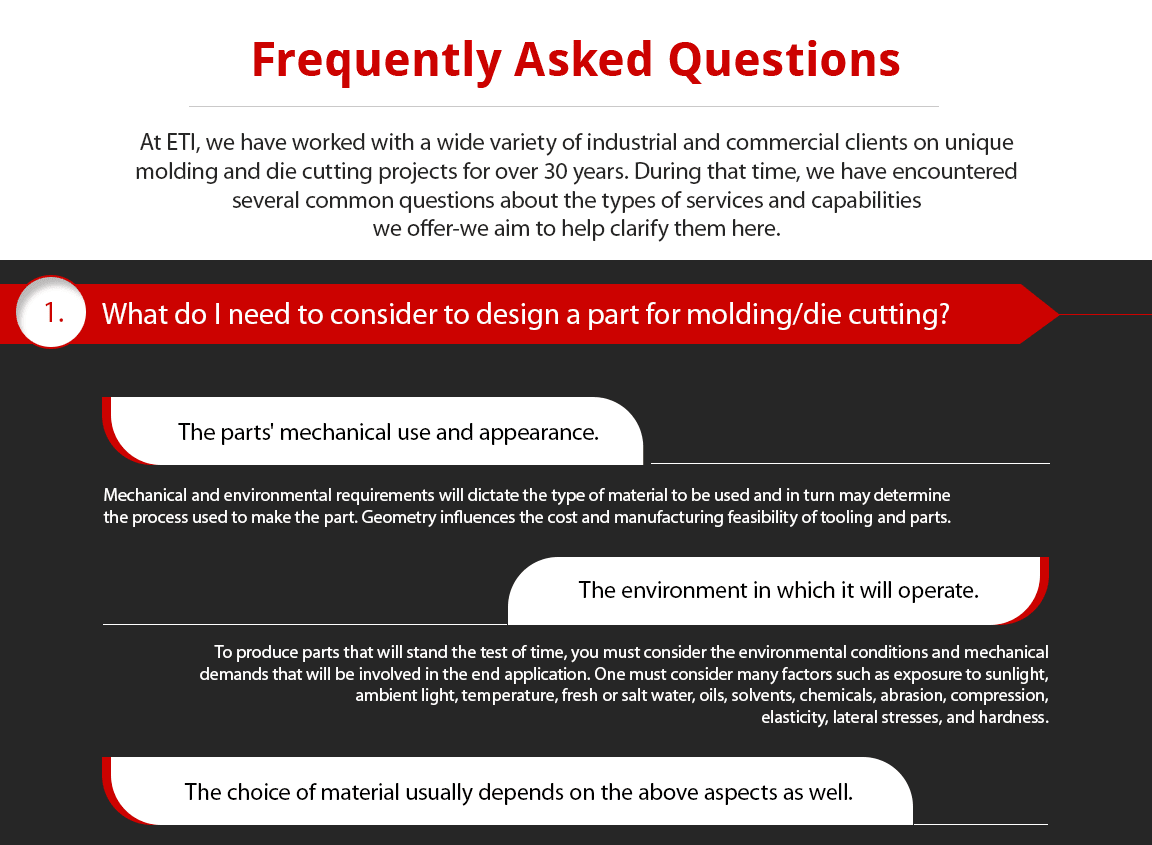

At ETI, we have worked with a wide variety of industrial and commercial clients on unique molding and die cutting projects for over 30 years. During that time, we have encountered several common questions about the types of services and capabilities we offer-we aim to help clarify them here.

Optimizing Your Design

The team at Elastomer Technologies, Inc. (ETI) aims to help each customer decide the best approach to their project. We collaberate with our customers to try and address all of the following considerations:

Material Selection

- Quality, function, repeatability and reliability are dependent upon material choice

- Cost of the part is directly influenced by the material used

- Is the material readily available? This has a bearing on delivery, cost and throughput

- Some materials are easier to process which lessens the cost to make a part

- Some materials require secondary operations that add to the cost of a part

- Selection of material may limit available processes

- One must consider all of the environmental factors a part will see in processing and in use

Mechanical and Environmental Requirements

- Dictates the type of material to be used and in turn may determine the process used to make the part

- One must consider many factors such as exposure to sunlight, ambient light, temperature, fresh or salt water, oils, solvents, chemicals, abrasion, compression, elasticity, lateral stresses and hardness

Part Geometry

- Geometry influences the cost and manufacturing feasibility of tooling and parts

- We look at thick and thin requirements, part transitions and variations

- Complexity that might lead to secondary operations or tooling maintenance issues

- Projected area and overall part dimensions may limit a process’s capacity to make a part

- Gating requirements and other dimensional requirements for molded parts that might influence tooling choices

- Dimensional or thickness requirements for die cut parts might be problematic for part quality and require a different approach

Special Considerations

- Color requirements

- Secondary operations or quality requirements that require special fixtures of tooling

- End of Arm tooling and automation

- Use of adhesives or primers

- Special testing of materials and certifications

- Custom packaging and labeling

- Assembly

- Quality testing requirements

- Supplier certification and auditing

Customer Project Goals

- Transfer of tooling and projects

- Meeting a price point

- Quality objectives

- Specific short term and long term delivery requirement

- Requirement to make a monetary investment to support a project

To kick-off your project with ETI, fill out our Design Analysis form, or reach out to the team for more specific details.

Project Forecaster & Design Analysis

We invite you to complete our brief Design Analysis form which will help us determine the correct material and process for producing your part. Once your form has been submitted, a member of our team will review your project’s demands and reach out you.

Click below to get started today.