At Elastomer Technologies, Inc., we provide a variety of rubber molding and die cutting services at our Corona, California facility to serve local and global clients alike. These services produce components with specific properties – such as durability, resilience in harsh environments, and flexibility – based on your unique requirements. As there are several types of rubber molding and die cutting services available, we feel it is important to share and help you to understand what they entail.

Rubber Molding, Injection Molding, & Die Cutting Services in California

With a focus on customer service, the experts at ETI can help to select the right process in order to produce the best results for your application’s requirements.

Rubber Molding

The rubber molding process involves converting uncured rubber compounds into finished rubber products using a steel or aluminum custom mold. Processes use either natural or synthetic source materials in a variety of formulations, depending on the desired properties in the completed product. Three of the main rubber molding processes that we use at ETI are:

Compression Molding

This rubber molding process involves the application of pressure to form a final product. Operators begin by molding pre-forms using raw material, and then apply pressure and heat to them in a molding cavity to give the material the cavity’s shape. At ETI, we utilize our clean room to offer customers FDA-compliant and food-grade compressed parts, and our state-of-the-art equipment allows for tight tolerances and aesthetically pleasing, durable components.

Transfer Molding

In transfer molding, operators place a specific amount of a cold, pre-catalyzed material into a chamber or pot above the molding cavity. Under the force of a plunger, the rubber presses through a small opening within the mold cavity to then take the mold’s shape. Transfer molding at ETI produces cost-effective and strong yet lightweight parts.

Prototype Molding

Prototyping allows us to test multiple design iterations against each other in real time. ETI offers three prototyping techniques:

- Pour molding with room temperature-vulcanizing (RTV) silicone

- Transfer or compression molding with liquid or high-consistency rubber (HCR) silicone

- Injection molding with liquid silicone rubber (LSR) or HCR silicone

Liquid Silicone Injection Molding

Using LSR and HCR, this injection molding process creates components that are durable, flexible, and resistant to extreme temperatures. ETI uses energy-efficient 50- and 100-ton injection molding presses to complete this process. For one such project here in California, we utilized liquid injection molding to custom-design disc valves for a client in the medical sector.

Die Cutting

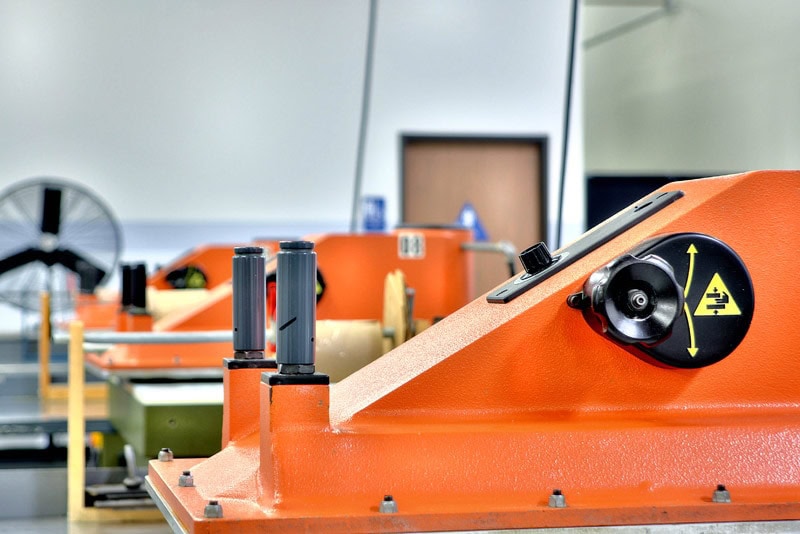

ETI has built a comprehensive offering of die cutting capabilities, such as high-speed automatic Preco systems, punch presses, clicker presses, and traveling heads. These systems enable us to manufacture a wide range of shapes, sizes, materials, and production volumes. Our services include traditional and high-speed die cutting as well as high-speed converting. As an example, for a local customer here in Corona, California, we applied high-speed die cutting to produce Neoprene foam foot pads.

Advantages of Working With ETI

When you turn to the experts at ETI, you will be tapping into a number of benefits with our rubber molding and die cutting services:

High Quality

From small production runs to orders for a million or more units, precision-built tooling enables us to generate components with complex geometries, consistent accuracy, and repeatability. For quality assurance, we comply with industry standards and have obtained ISO 9001 and ISO 13485 certifications. For more sensitive projects, ETI uses ISO Class 8 clean room molding as well as a Class 100,000 clean room to reduce contamination.

Cost-Efficiency

At ETI, we strive to offer our customers swift turnaround and reduced costs. In line with these goals, our facility features lights-out manufacturing that reduces time and labor costs, automating large production runs with robots and end-of-arm tooling. Automation is also a part of some die cutting projects, depending on the material. We offer prototype molding services to generate functional parts for testing, minimizing any reworking during the production phase. Our company prioritizes waste reduction as well, and our cold deck systems and efficient material delivery assist us in this goal.

Expertise

Since 1975, ETI has provided molding and die-cutting services to an incredibly diverse range of industrial customers. With a focus on innovation, we developed our proprietary design analysis tool, Project Forecaster. This helps our customers determine which processes and materials could be the right fit for their specific needs.

Our extensive portfolio highlights examples of our successful past projects.

Partner With ETI

ETI’s Corona, California facility provides top-notch services and advanced technologies to clients worldwide. To determine if rubber and injection molding or die cutting is right for your application, contact us to find out more about our capabilities or request a quote to start your project.