With over 35 years of experience Elastomer Technologies, Inc. (ETI) offers custom die cutting using multiple processes including high speed automatic Preco work centers, as well as clicker, travelling head, and punch presses to accommodate a range of materials, component shapes, and production volumes.

ETI’s die cutting capabilities include the ability to cut rubber, plastics, foam, sponge, hook and loop, film, adhesives, and packaging materials to close tolerances. Adhesive backed materials can also be kiss-cut as requested.

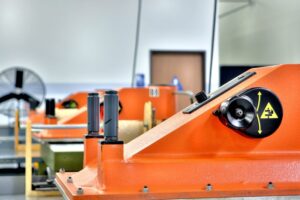

High speed presses can be used to efficiently cut high volume components while stamping presses are ideal for precision cutting applications. By maintaining multiple types of cutting equipment, we are able to provide versatile and efficient contract services for a range of applications.