Injection molding is a manufacturing technique in which the molten material is injected into a hot mold cavity under high pressure. The material then cures and solidifies within the mold, taking its shape.

When To Use Rubber Molding

Rubber molding is a versatile and cost-effective manufacturing process used in many industries for decades. It involves heating a rubber material and then pressing it into a mold to create a product with precise dimensions and intricate details. Moreover, it offers several advantages, including enhanced durability, flexibility, and affordability. However, the technique may not be…

Benefits of Liquid Injection Molding for the Medical Industry

Injection molding is a versatile manufacturing technique used in the silicone industry for over a century. In particular, liquid injection molding (LIM) is a medical device manufacturing process with several advantages over other methods.

Rubber Molding vs. Rubber Extruding: What Are the Differences?

Rubber is a very versatile material. It is used to manufacture a wide range of parts and products, from seals and gaskets to tubes and hoses to bumpers and grommets. As part of this, rubber can be subjected to a variety of manufacturing processes. Each process entails different techniques to turn the raw material into…

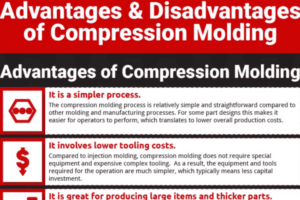

Advantages and Disadvantages of Compression Molding

Compression molding is a molding method that utilizes custom machined molds to form parts and products from uncured rubber or plastic. The process involves placing the material into the open mold cavity, closing the mold, and applying heat and pressure to shape and solidify the material into the desired component. It can be used to…

What is Compression Molding?

“Molding” is an umbrella term encompassing all of the processes that utilize molds to shape material (typically rubber or plastic) into the desired parts and products. Manufacturers are able to employ a variety of molding methods to suit different product and production requirements. One of the most commonly used methods is compression molding. What Is…

A Guide to Compression Molding

Compression molding uses a heated mold in combination with precise amounts of material and applied pressure to create solid components from a wide range of available and custom formulated materials. In this blog, we offer a concise overview of the compression molding process, its benefits, and its uses for various industries. What is Compression Molding?…

Which Rubber Molding Process Is Right for Your Project?

Rubber molding is a manufacturing process that uses pre-shaped molds to create parts and components from uncured rubber. Depending on the product and specifications, there are several different rubber molding method options—such as compression molding, transfer molding, and injection molding—each of which comes with unique considerations and best use cases. In the following blog post,…

Liquid Injection (LIM) vs. Compression vs. Transfer Molding

Liquid injection molding, compression molding, and transfer molding are characterized by a number of both shared and unique qualities. The following blog post explores each of these three molding techniques, outlining their similarities and differences, pros and cons, and applications. Liquid Injection Molding (LIM) Liquid injection molding (LIM) utilizes liquid silicone rubber (LSR) or similar…