Die cutting is a crucial manufacturing process that utilizes specialized machinery to cut materials efficiently into precise shapes. Outsourcing die cutting services to professionals guarantees precision and quality, which are vital for functional and attractive products. With expertise in precision cutting techniques, professional services help businesses avoid defects, material waste, and financial losses, ensuring each…

How To Choose the Right Die Cutting Partner

Die cutting is a manufacturing process that involves cutting out shapes from stock materials using a die, a specialized tool designed for cutting or shaping. This technique uses materials like paper, fabrics, rubber, metal sheets, and plastics.

Benefits of Reshoring Die Cutting

Manufacturers are gradually turning to reshoring, particularly in metal cutting and forming processes like die cutting. One reason is the increased customs complications caused by the COVID-19 pandemic, which demonstrated the potential risks with offshoring operations.

What You Need to Know Before Starting a Die Cutting or Molding Process

The ETI team often gets inquiries from companies and folks that are new to manufacturing a molded elastomer/rubber or die cut product. In this blog, we’ll talk about some of the recommendations we provide to anyone looking to start their molding or die cutting project, particularly for the first time. Communicating Your Die Cut or…

Die Cutting: Steel Rule, Custom Punch, & Matched Metal

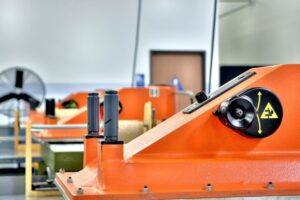

Die cutting is a manufacturing process that uses specialized cutting machines and cutting tools—i.e., dies—to cut patterns into thin, flat material. There are several types of die cutting processes, all of which employ four basic components: the operator, the material, the cutting machine, and the cutting die. Cutting dies are available in many different designs…